*SARAH MEHRABI

(TEHRAN_SANATNAMA)- The textile industry is a group of related industries that employs a wide range of natural fibers such as cotton, kapok, fake, sisal, banana fiber, agave, flax, jute (hemp), hemp, hemp stem, ramie, bamboo, hair , Wool, coconut fiber, asbestos (asbestos), sheep's wool, goat's cashmere, moir (high quality) goat's, alpaca's fleece, horse wool, silk and other or fibers Synthetic such as polyamide nylon, PET or PBT polyester, phenol-formaldehyde (PF), polyvinyl alcohol (PVA), polyvinyl chloride (PVC) fibers, polyolefins (PP and PE), acrylic polyesters, logo Uses iodine, polyethylene (PE), elastomer, spandex, polyurethane and more.

The subdivisions of the textile industry can be approached through its various components through several aspects. According to research sources, the classical method of classifying the industry consists of grouping factories according to processed fibers, ie cotton, wool or synthetic fibers.

However, the modern approach to classifying the textile industry, including the classification of manufacturing plants, according to their specific functions such as fiber hooking, spinning, weaving (blending and weaving), knitting (knitting with two rods), needlework, garment production And so on.

New innovations in garment manufacturing, manufacturing and design have emerged since the industrial revolution that changed these cycles, knitting machines and spinning processes forever.

The "Textile Fabric Trade" in the UK and Australia refers to the manufacture, trade and distribution of textiles.

There are various stages in the historical perspective, the stages in which the textile industry evolved from a small-scale indigenous industry to the dominant state it currently stands. The rural phase was one of the earliest stages in the industry's history in which textiles were produced locally.

During this period, fabrics were made of materials such as wool, linen, and cotton. The material depended on the area in which the fabric was made and when it was made.

In the second half of the Middle Ages, in parts of northern Europe, cotton was considered as imported fiber. During the later stages of the sixteenth century, cotton grew in the warm climate of the Americas and Asia. When the Romans ruled, wool, leather, and flax were the materials used to produce garments in Europe, while linen was the raw material used in northern Europe.

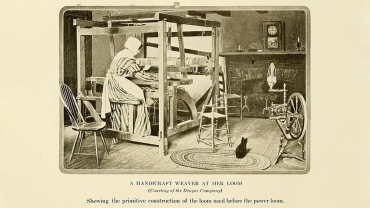

During this period, surplus fabric was purchased by merchants who visited different areas to produce the remaining pieces. A variety of processes and innovations have been implemented to produce garments during this time. These processes depended on the materials used, but there were three basic stages commonly used in garment manufacturing. These steps included preparing fiber materials for the purpose of spinning, weaving, and knitting.

During the industrial revolution, new machines such as spinning wheels and hand-knitting machines came into production. Material production for garment manufacturing quickly became an organized industry, so much different than the local activities associated with it before. A number of new innovations led to the industrialization of the textile industry in Great Britain. Clothes made during the Industrial Revolution formed a large part of the exports made by Great Britain. They accounted for about 5 percent of total artifact exports at that time, doubling between two and three.

The center of cotton industry in Great Britain was Lancashire, and the quantity of cotton exported increased from 2 to 3 times, 5 times. However, wool was the most important export item at this time.

During the Industrial Revolution, a great effort was made to increase production speed through the inventions of the Macaw Launcher of the Year 2, the Flyer-Pulley System and the Roller Spinning Machine by John White and Louis Powell in Year 2.

Louis Powell later invented the carding machine later in the year, and Jenny's spinning machine was developed in the second year. The Blue Machine was invented in the year 6 by Richard Ercright. The power weaving machine was invented in the 2nd year by Edmund Cartwright.

In the early stages, the textile mills were located near and around the rivers because of the power of the water wheels. Since the invention of the steam engine, dependence on rivers has largely disappeared. In the later stages of the 20th century, macaques used in the textile industry developed and became faster and more efficient. This has led to the replacement of older Macs with the newer ones.

Nowadays, modern techniques and innovations have led to the emergence of a lower and more competitive textile industry offering almost any type of fabric or design that one wishes to possess. China has mastered the textile industry of the world by using cheap labor.

END NEWS/

آخرین ویرایش در 06/12/1398