CHELTENHAM – Advanced materials supplier Versarien says it has signed a Letter of Intent (LOI) with an Asian apparel manufacturer as the pair look to develop and commercialise graphene-enhanced footwear.

Technical Textiles are defined as materials and products manufactured primarily for their technical and performance properties rather than their aesthetic or decorative characteristics.

Apparel manufacturers inspect the fabric stock upon arrival, so that any fabric irregularities are caught early in the production proce.

Ask any fashion or textile company owner and they will tell you that having the right production facility to manufacture their goods is one of the most important elements of their business.

Nanotechnology has helped revolutionise the concept of smart textiles with various offerings in terms of performance, comfortability, cleanliness and current needs. The market for nanotechnology-infused textiles has risen rapidly from $20.3 billion in 2008 and is projected to reach $205 billion by 2022, representing 16 per cent of the global textile industry by value.

Fiber is the fundamental component required for making textile yarns and fabrics. There are two types – natural and synthetic. Natural fibers come from animals (sheep, goats, camelids, etc.) or vegetable-based fibers (cotton, flax, linen, and other plant fibers). Mineral fibers (asbestos, etc) are also classified as a natural fiber.

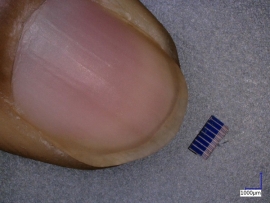

Scientists from Nottingham Trent University have developed a technology to embed miniaturised solar cells into yarn that can then be knitted and woven into textiles. This can lead to clothing embedded with tiny solar cells the size of a flea which will allow wearers to generate electricity on the move and charge items like mobile phones and smartwatches.

A new report on pricing sponsored by Precima, conducted by Retail Systems Research (RSR) namely ‘Pricing 2016: Life Becomes Unmanageable’ reviews current pricing practices and challenges faced U.S. retailers.

Packaging tape will stick to most surfaces merely by applying pressure. The tape is made of a coated adhesive, which is backed by a non-sticky materials like paper, foil, fabric, or movie. There are several different grades & types of packaging tape products to suit varying packing demands. Polyethylene plastic tapes or poly tapes, most commonly used for packaging and for sealing light weight carton boxes subject to normal shipping and transport hazards.

The rapid spread of COVID-19 has severely impacted the global cotton supply chain. An unexpected reduction in cotton mill use data is observed across all of the major cotton spinning countries, including China, India, Pakistan, Bangladesh, Turkey and Vietnam.